Testing Equipment

Testing Equipment

At Purofiltec, we understand the critical importance of maintaining optimal filter integrity within your industrial processes. Contaminated or compromised filters can lead to inefficiencies, product inconsistencies, and even potential safety hazards. Our Bubble Point Test Units provide a reliable and efficient method for ensuring the integrity of your disc and candle filters, allowing you to maintain peak filtration performance and product quality.

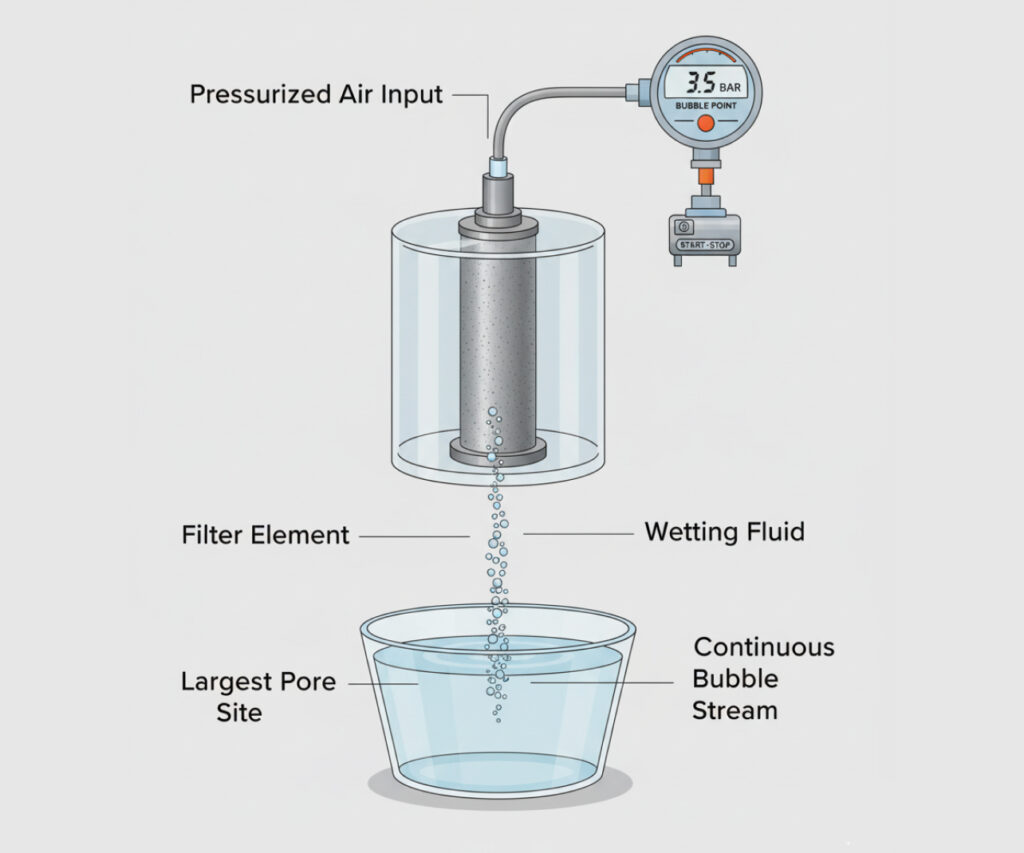

What is a Bubble Point Test?

A Bubble Point Test is a non-destructive testing method used to determine the largest pore size within a wetted filter element. During the test, compressed air is gradually forced through the filter media. The Bubble Point is the precise differential pressure at which the first continuous stream of air bubbles emerges from the filter element.

Purofiltec Bubble Point Test Units

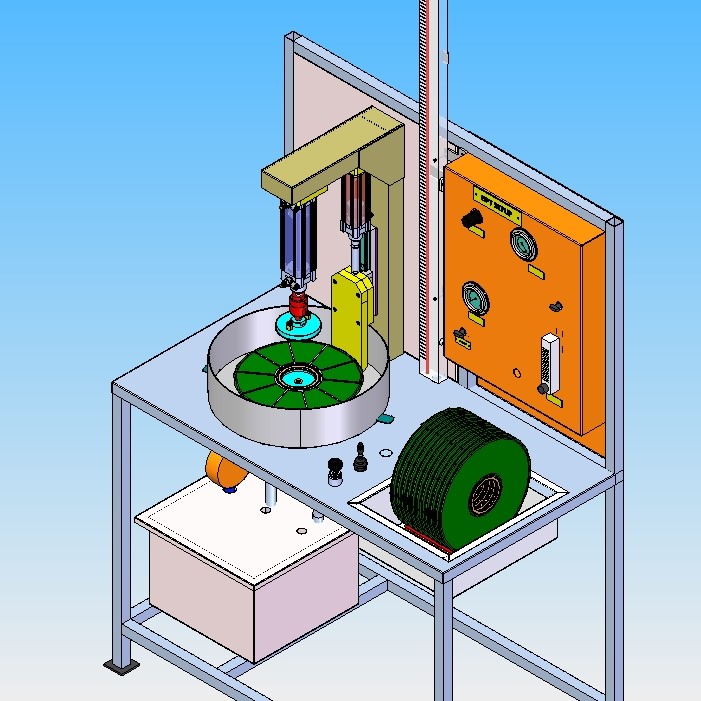

This unit is specifically engineered to effectively test the integrity of your disc filter elements. The design incorporates features that ensure accurate and reliable testing, providing you with the critical data you need to make informed decisions about your filtration system’s maintenance. The BPT Unit – Disc Filter is constructed with high-quality materials to withstand the demands of industrial environments. It features a user-friendly interface that simplifies the testing process for operators of all experience levels. Additionally, the unit is designed for compatibility with a wide range of disc filter element sizes and configurations, ensuring its versatility within your filtration system.

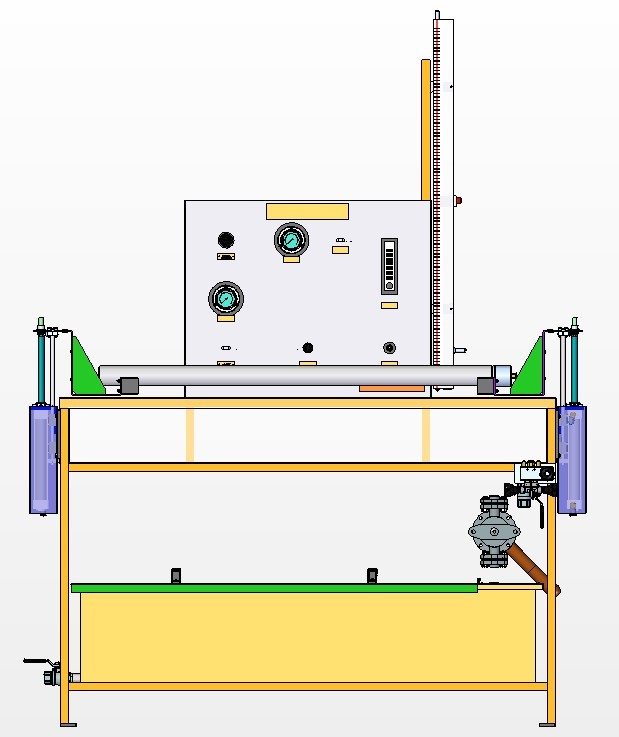

Our BPT Unit – Candle Filter is meticulously designed to accommodate various candle filter element configurations, ensuring seamless testing regardless of the specific design of your filters. The unit features a user-friendly interface that simplifies the testing process, even for operators with limited experience. The BPT Unit – Candle Filter is constructed from durable materials to ensure long-lasting performance within industrial environments. It provides accurate and reliable testing results, allowing you to make informed decisions about the maintenance and replacement of your candle filter elements. By incorporating the BPT Unit – Candle Filter into your routine maintenance procedures, you can proactively identify and address minor changes in the Bubble Point, preventing potential filter failures and safeguarding the integrity of your filtration system.

Bubble Point Unit for Candle Filters

Bubble Point Test Units for Candle Filters are automated systems for detecting the first bubble, ensuring filter integrity and performance, and optimizing filter selection and maintenance.

- Accurate pore size measurement

- Integrity testing

- Contamination prevention

Bubble Point Unit for Disc Filters

Bubble Point Test Units for Disc Filters are designed to accurately measure filter pore size and integrity, ensuring optimal performance and preventing process contamination.

- Accurate pore size measurement

- Integrity testing

- Contamination prevention